APPLICATION

An oil separator tank designed to separate oil from water prior to being discharge to drainage for compliance with local

regulatory requirement. It is suitable for use in gas station, car wash, garage, workshop, or other source that discharge

oil-contaminated water in non-emulsified form.

PROCESS DESCRIPTION

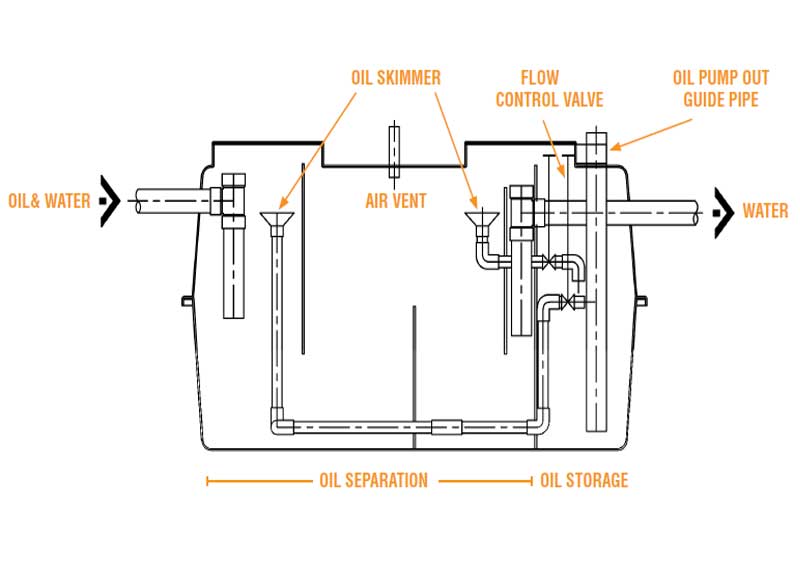

BIOTECH B-OIL Series comprises of two main compartments:

OIL SEPARATION – Enhance natural gravitational flotation of oil to top surface inside this chamber by providing baffles to control internal flow direction. This chamber also include skimmers for collection of separated top oil layer to be stored in a subsequent chamber. Relatively clear water is allowed to pass through baffles and outlet pipe for discharge to drainage.

OIL STORAGE – Separated oil for the first chamber is skimmed and collected in this chamber to be emptied by external pumping equipment each time it is refilled with oil. A guide pipe is provide for easy insertion of pump hose. Valves are also provided to temporally shut off oil flow.

INSTALLATION

UNDER-GROUND – Up to 60 cm depth measuring to manhole level is supported for standard model. Deeper installation is

also supported with customizable tank thickness from factory.

ON-GROUND – Can be place above ground and receives oil-contaminated intake from submersible pump via external lifting station.

MATERIAL

Fiberglass Reinforced Plastics (FRP) material provides at minimum of 4x more tensile strength in comparison to plain plastics materials such as polyethylene (PE). This allows FRP tank to resist heavy top load from soil, pedestrians and light vehicles while having longer lifespan

in contrast to plain plastics.

TESTING & CERTIFICATION

All tanks must pass hydrostatic test post-production to ensure that no leakages and excessive deformation. Each tank model undergoes vacuum test according to CAN-CSA-B66 standard to verify its load bearing capability against designed tank burial depth and thickness.

All tanks are produced under production process certified under ISO 9001:2015.